Case Studies

Specific Usage Examples

We would like to introduce some specific examples of how SmartBarcode is used and contributes to the needs of each client, which vary greatly from client to client.

case#01

Sankyu Corporation

(PoC)

Sankyu Corporation (PoC)

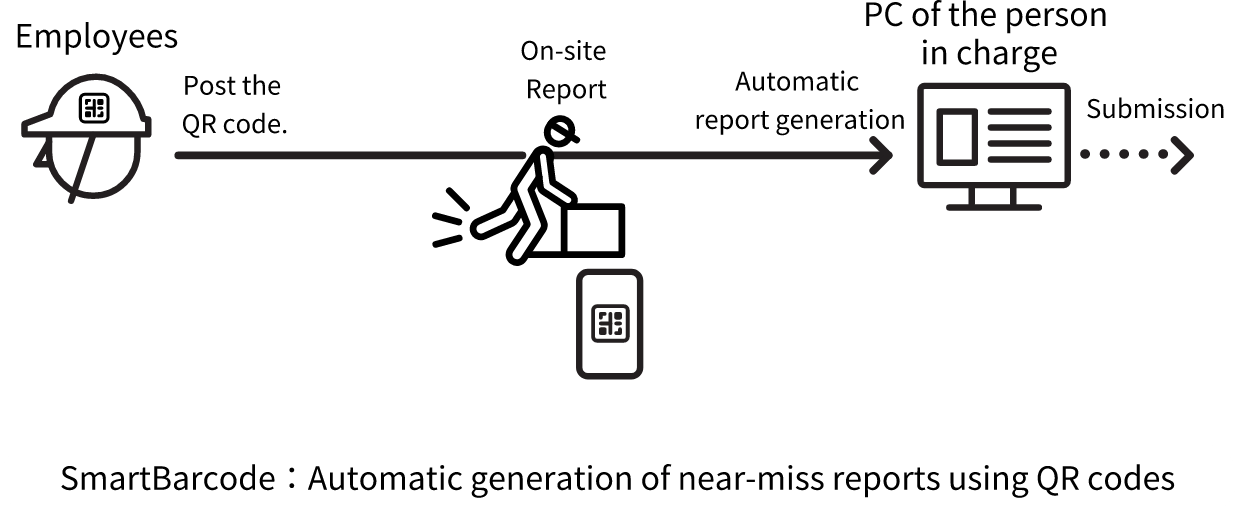

Safety Management in Warehouses, etc.

Hiyari-Hatto can be prevented through reporting of the incidents that occurred, and through accumulation of causes and analysis of countermeasures. With smart barcodes, near-misses can be shared in real time, and reports can be easily generated. Visualization of the details of the incident leads to employee alerts.

case#02

Mitsubishi Warehouse Co.

Mitsubishi Warehouse Co.

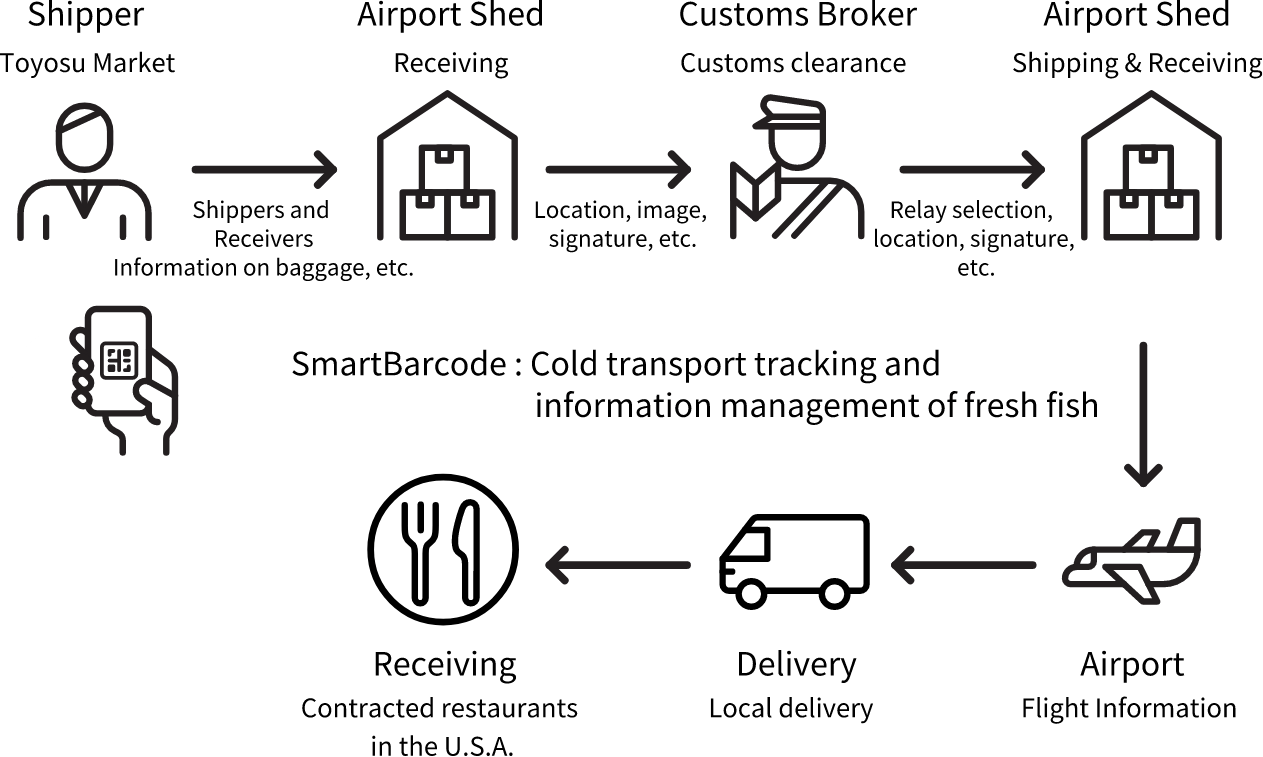

Visualization of cold transport

SmartBarcode is used to track cold shipments of premium fresh fish to the U.S. SmartBarcode can also share flight information, enabling flexible response to cases such as sudden changes in flight times due to inclement weather, minimizing losses.

case#03

XEBIO Holdings Co.

XEBIO Holdings Co.

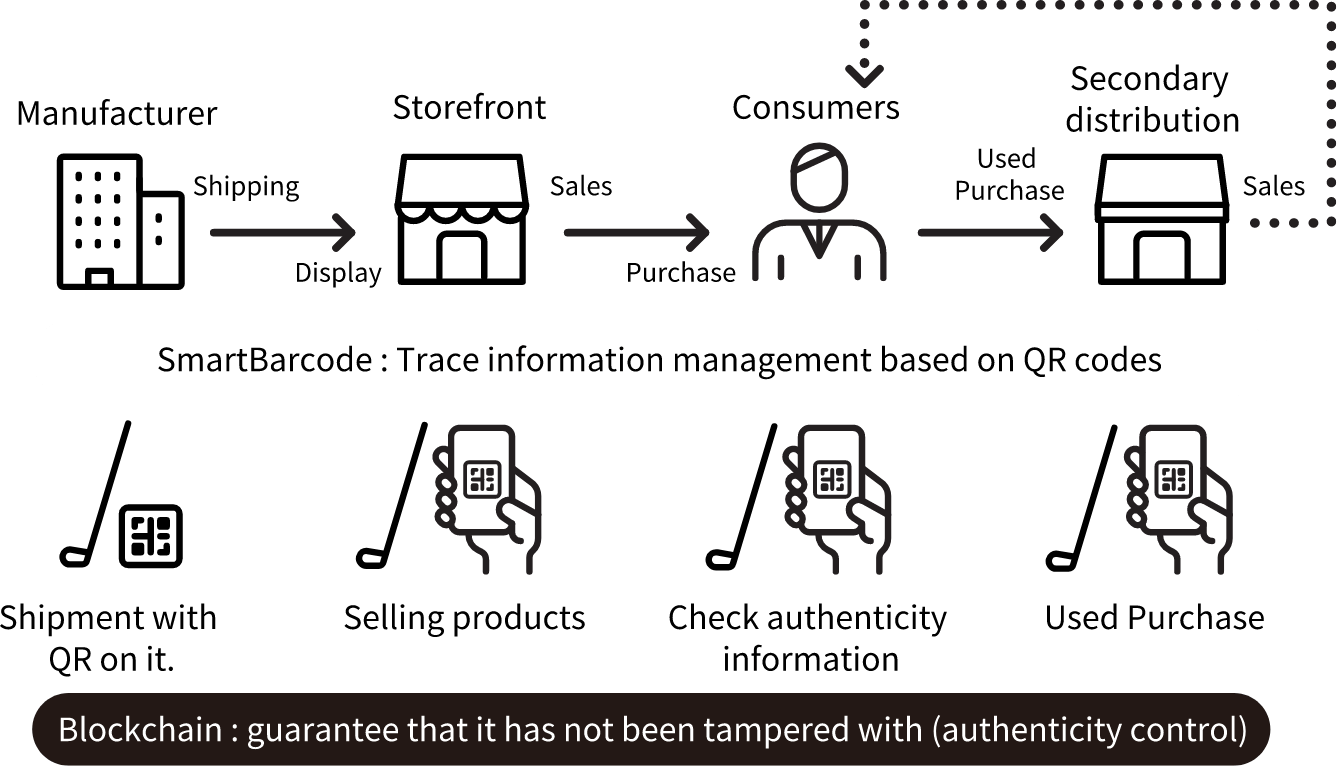

Authenticity check

The XEBIO Group is developing and operating a new blockchain technology-based authenticity system, X2nd, for managing the authenticity of sporting goods.

case#04

SANKYU SAL

SANKYU SAL

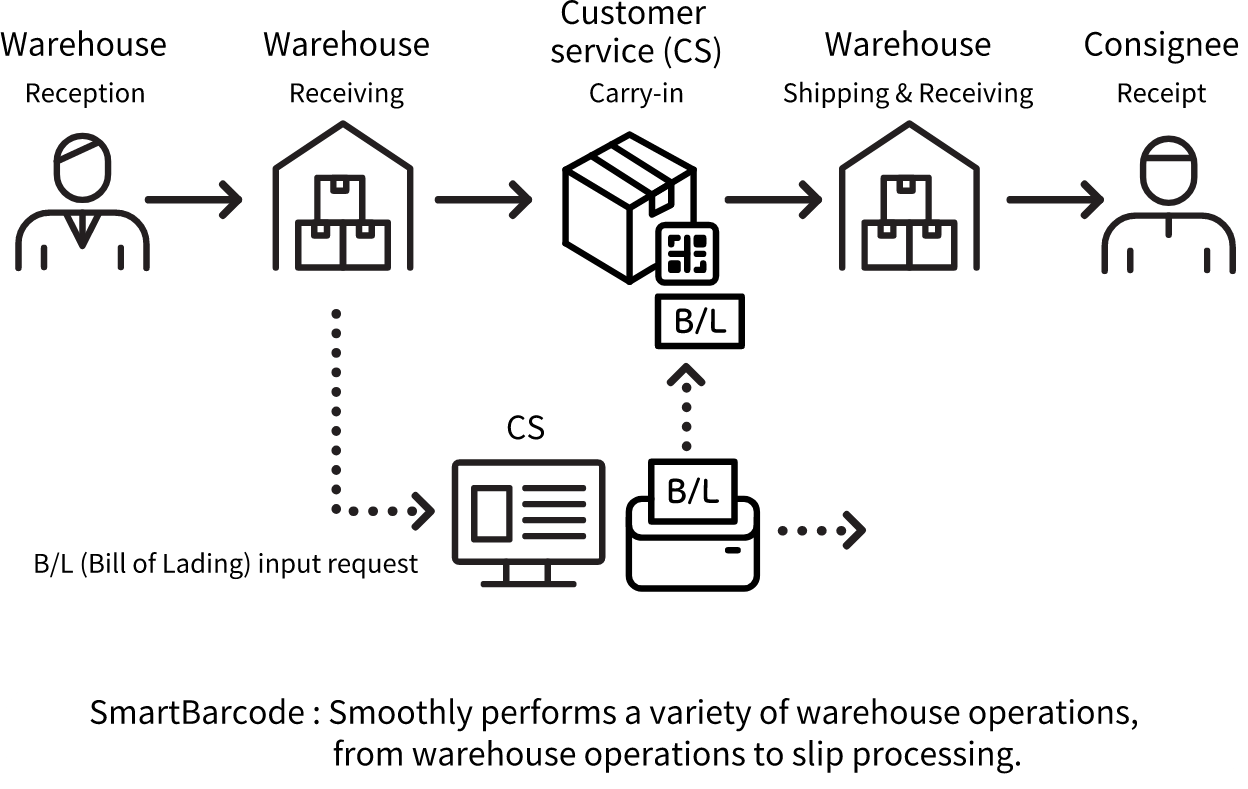

Warehouse operations receiving and shipping management and transportation tracing

The system automatically generates a warehouse receipt by scanning the barcode at the time of receipt, and pairs the cargo barcode with the barcode on the cargo label issued based on the bill of lading number entered at the office to prevent incorrect shipments.

Main applications

It can be utilized in a variety of other areas

in line with your company’s needs.

Generation and

output of forms

Any form can be generated reflecting various information (validation information and tracing information) associated with barcodes. Data can be imported into any form, such as P/O, receiving slips, B/L, and daily work reports.

Procurement

Management

By “smartening” the barcodes assigned to materials by suppliers at the time of receipt and making them traceable, process control can be performed directly on the production line.

Food Value Chain

Traceability of perishable food products can be linked to barcodes for production processes of producers, logistics tracing to visualize freshness, and processing management information such as HACCP, etc., to provide consumers with transparent information on “food safety/reliability”.

Manufacturing

Management

Visualize manufacturing management by linking raw material source information to product barcodes during processing, and pairing product names and lot numbers of various parts to products.

Temperature /

Humidity Control

By linking temperature loggers, humidity loggers, etc. with barcodes via API, it is possible to graph on a smartphone how temperature and humidity have changed between tracking points (in storage, during transportation, after receipt, etc.).

Authentication

By storing barcode trace data as hash values in the blockchain network of Zero Bill Bank Japan, with which we have a business partnership, it is possible to determine the authenticity of products and other items in the supply chain.